PARTNER : BORRELLY SPRING WASHERS

The difficulty of achieving springs using pure strains (here compression and traction) resides in the small displacement authorized by such solicitations. One approach is outlined with conventional washers called » BELLEVILLE » where the tensile stress – compression prevails, but where it resides a proportion of flexion in the part large enough to make the efficiency of this type of spring insufficient for our application.

However, these washers transform small deformations in large displacements, which is sought in the springs. However, the stress distribution (Von Mises) in BELLEVILLE washer is not uniform, which weakens its effectiveness.

C&T went at the end of this logic and offers a patented design for the joint use of pure tensile stress and compression while providing significant travel.

The proposal C&T relies on a spring having:

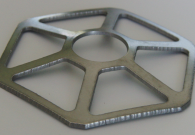

- An outer ring

- An inner ring

- Radius connecting the inner ring to the outer ring

The whole is generally a conical shape; the spring can be easily made by cutting an existing BELLEVILLE washer.

The axial compression of the spring tends to put back spring in flat position, which causes the extension of the outer ring and the inner ring compression as rays. The recesses in the rays allow giving the part a flexibility ensuring a very low participation as a way of bending stress.

The stressed areas are almost pure tension or compression.

A judicious design concept provides a limit tensile stress in the outer ring in identical to limit compressive stress in radius as in the inner ring. This design allows accumulation of an optimal energy in spring.